There are many cutting methods under different conditions. In this case the requirements of cutting tools, they require some unique properties. In order to obtain this performance, cutting tools are made of different materials. The material selected for a specific application depends on Depending on the materials processed, the type of processing, the quantity and quality of the products. Carbon tool steel was first used in cutting processing, and later various tool materials such as carbide, high-speed steel, ceramics, cubic boron nitride, and artificial diamond were developed. In terms of usage, more than 95% of machine tools are currently made of carbide and high-speed steel.

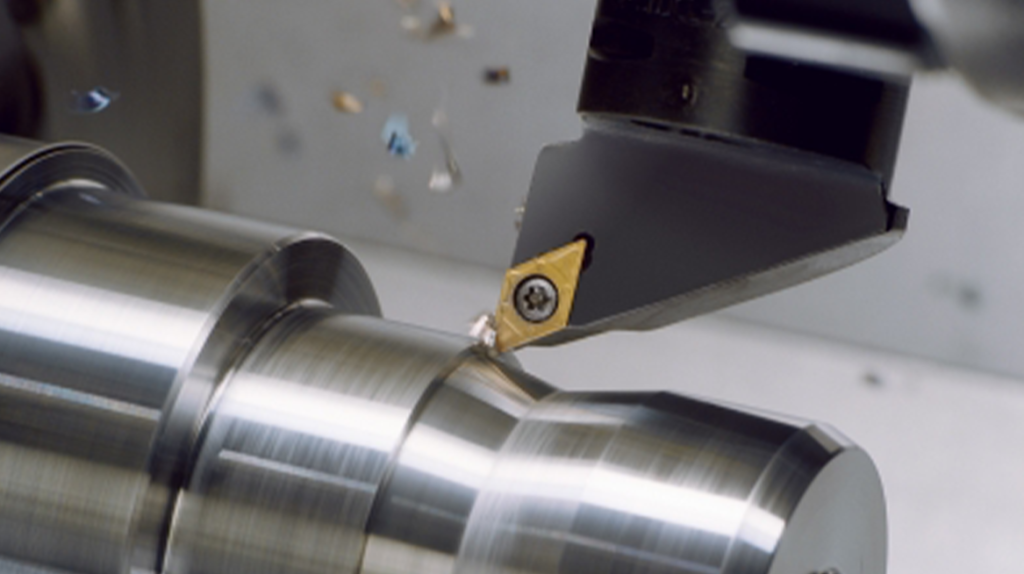

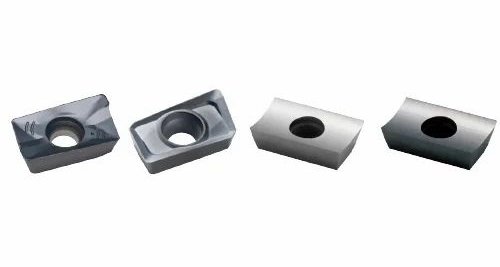

1. Carbide

Carbide cutting tools are used in powder metallurgy technology production. It is composed of tungsten, tantalum and titanium carbide, with cobalt as the binder (when the binder is nickel or molybdenum, it is called a cermet). It can be mainly divided into: tungsten-cobalt cemented carbide, tungsten-cobalt-titanium cemented carbide, and new cemented carbide. Carbide cutting tools are very hard; they can withstand very high speed cutting operations. Carbide cutting tools do not lose hardness up to 1000°C.

High-cobalt tools are used for roughing, while low-cobalt tools are used for finishing.

Cutting speed range: Vc=60-200 m/min

Temperature: 1000°C.

Hardness: up to HRC 90

2. High speed steel

This is a type of high carbon steel that contains large amounts of alloying elements such as tungsten, molybdenum, chromium, etc. To improve hardenability, toughness and wear resistance. It provides higher metal removal rates. At moderate temperatures around 650°C it loses hardness. Therefore, coolant should be used to increase tool life, and through grinding, it can be used multiple times. Perform some surface treatments on high-speed steel to improve its properties.

Surface treatments used in high speed steel:

Polishing – reduces friction

Nitriding-increases wear resistance

Chrome plating – reduces friction

Oxidation – reduces friction

High-speed steel materials can be used to manufacture: drill bits, milling cutters, broaches, etc.

Cutting speed range: Vc=30-50 m/min

Temperature: 650°C

Hardness: up to HRC 67

3. Carbon tool steel

It is a cheap metal cutting tool for low-speed machining operations. These ordinary carbon steel cutting tools have 0.6-1.5% carbon and very small amounts (<0.5%) of manganese and silicon. Other metals such as chromium and vanadium are added to change the hardness and grain size.

High carbon steel resists wear and maintains a sharp edge. Carbon tool steel has good machinability, but the material loses hardness rapidly at temperatures around 250°C. Therefore, it cannot be used in high-temperature applications, which may be irreplaceable in current machining operations.

Carbon steel tools are used in twist drills, milling tools, turning and forming tools for soft materials such as brass, aluminum and magnesium, etc.

Temperature: 450°C

Hardness: up to HRC 65

4. Ceramic materials

The most common ceramic materials are aluminum oxide and silicon nitride. The ceramic material powder is then compacted and embedded into the required blank shape for sintering.

Ceramic tools are chemically inert, resistant to corrosion, they have high compressive strength, they remain stable at temperatures up to 1800°C, are 10 times faster than HSS, have very low friction between the tool surface and the chip, and have With low thermal conductivity and typically no need for coolant, ceramic cutting tools can provide a very good surface finish.

Cutting speed: Vc=300-600 m/min.

Temperature: 1200°C

Hardness: up to HRC 93

5. Cubic boron nitride (CBN)

This is the second hardest material after diamond. They are commonly used in manual equipment. They have high wear resistance and can be used as abrasives in grinding wheels. Their use with sharp edges is not recommended.

Cutting speed: Vc=600-800 m/min

Hardness: higher than HRC 95

6. Artificial diamond

It is the hardest material known and also the most expensive. It has high thermal conductivity and melting point. Diamond has excellent wear resistance, low friction coefficient and low thermal expansion. It has the ability to process very hard materials such as carbides, nitrides, glass, etc. Diamond cutting tools have good surface finish and dimensional accuracy.