Metals have a wide range of applications in various industries. Product designers often use corrosion-resistant metals in a variety of applications, from aerospace components, musical instruments, heat exchangers to structural components.

While these metals offer excellent heat resistance and structural strength, like most metals, they vary in their ability to resist corrosion. Therefore, it is crucial to use metals with corrosion resistance properties that best suit the requirements.

Today’s in-depth look at corrosion-resistant metals and typical corrosion-resistant metals. Read on to the end to learn more about the best ways to improve your metal’s corrosion resistance!

To order inserts from us, please contact WhatsApp: +86 13890000254 or email: sales@marsloy.com

1. What are corrosion-resistant metals?

Corrosion-resistant metals are materials that are highly resistant to chemical breakdown caused by moisture, oxygen, or other substances. These metals, such as stainless steel, aluminum, titanium, and certain alloys, contain materials that form a protective oxide or passivation layer to prevent deterioration.

This property makes them ideal for use in harsh environments such as marine, chemical processing and outdoor construction where durability and longevity are critical.

2. Common corrosion-resistant metals

There are many types of corrosion-resistant metals, each with special properties and uses. We’ll explore typical corrosion-resistant materials below:

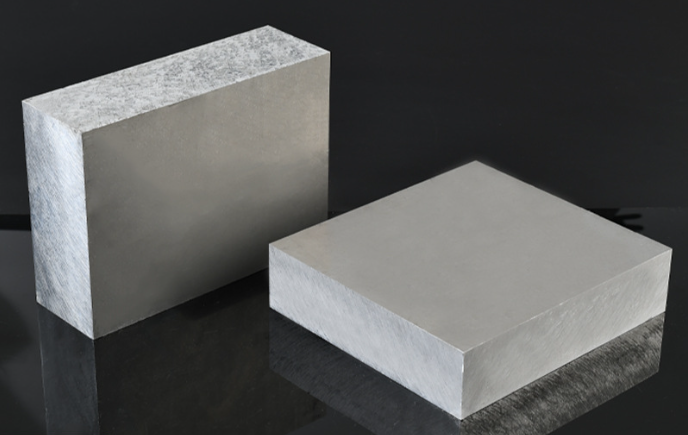

2.1 Aluminum

Aluminum is a standard workhorse metal for a variety of applications. Aluminum metal exhibits good corrosion resistance due to the passivating oxide layer formed on its surface.

The 1xxx, 3xxx and 5xxx aluminum grades exhibit the greatest corrosion resistance, although most grades of aluminum in the series exhibit higher chemical resistance

-1xxx Series: This grade of aluminum is up to 99% pure and offers excellent corrosion resistance in typical applications.

-3xxx series: This series uses manganese as the main alloy element. Therefore, its corrosion resistance is lower than that of 1xxx aluminum. However, its high ductility is well suited for cold forming applications where corrosion resistance is required.

-5xxx Series: 5xxx grade aluminum contains high manganese content and has similar corrosion resistance to 3xxx aluminum.

-6xxx Series: The 6xxx Series offers a balance of corrosion resistance, strength and workability and is popular in structural applications.

2.2 High temperature alloy

These are specially designed high-performance metals that provide excellent corrosion resistance and mechanical properties at high temperatures. Therefore, these grades of corrosion-resistant metals are used in energy and aerospace applications. However, superalloys set them apart.

Cobalt superalloys: Cobalt superalloys are metals with excellent resistance to hot corrosion and have a melting point higher than other superalloys.

Nickel-based superalloys: Nickel-based superalloys are the most commonly used superalloys because they are usually cheaper than all cobalt-based superalloys. These metals have high strength and excellent corrosion resistance.

Iron-based superalloys: This type of superalloy has high corrosion resistance and strength at room temperature. They are more economical than nickel-based and cobalt-based superalloys.

2.3 copper alloy

Pure copper and its alloys, including bronze (copper and tin) and brass (copper and zinc), are corrosion-resistant. Due to their excellent resistance to corrosive elements, these red metals are widely used in electrical, plumbing, construction and marine applications.

2.4 stainless steel

Manufacturers use a variety of stainless steel alloys in a variety of applications in industries such as food processing, chemical processing, automotive, pharmaceuticals and construction. These alloys can be divided into three broad categories based on their microstructure, including:

- Stainless steel is a term that covers a variety of corrosion-resistant metals. The constituent elements of a steel alloy determine its corrosion resistance. Steel alloys have excellent corrosion resistance, making them suitable for use in environments with high temperatures and corrosive chemicals. The chromium content forms a chromium oxide passivation layer on its surface, protecting it from degradation.

- Austenitic Stainless Steels: These alloys are generally considered 300 series stainless steels. Stainless steel 304 and 316 are typical grades of this type of stainless steel. Depending on the grade, austenitic stainless steel typically contains alloying elements including 18% chromium and 8% nickel, with smaller amounts of manganese and nitrogen. This series of alloys are the most corrosion-resistant metals on the market.

- Ferritic stainless steel: Ferritic stainless steel belongs to the 400 series of stainless steels. This family of alloys typically contains a higher chromium content of approximately 27%, which increases their durability. However, due to its lower carbon content, it is more ductile. 430A is the typical stainless steel alloy in this category.

- Martensitic Stainless Steels: These are 400 series stainless steel alloys. 420A is a widely used steel alloy in this category. It contains 18% chromium, a higher carbon content, and is nickel-free. Although martensitic stainless steel is harder than other corrosion-resistant metals, it is less corrosion-resistant than 300 series steel.

For more information about stainless steels, please refer to our previous post:

2.5 titanium

Titanium has a wide range of applications in the aerospace industry due to its excellent strength-to-weight ratio. Manufacturers often use titanium for industrial applications due to its excellent corrosion resistance. As with most corrosion-resistant metals, the passive oxide layer on titanium’s surface is key to its corrosion resistance.

However, if the passivizing oxide layer breaks off, it will quickly re-form in the presence of moisture and oxygen. Titanium’s excellent corrosion resistance makes it a popular material in applications that use chlorine solutions, such as the chlor-alkali industry, because of its extraordinary resistance to these chemicals.

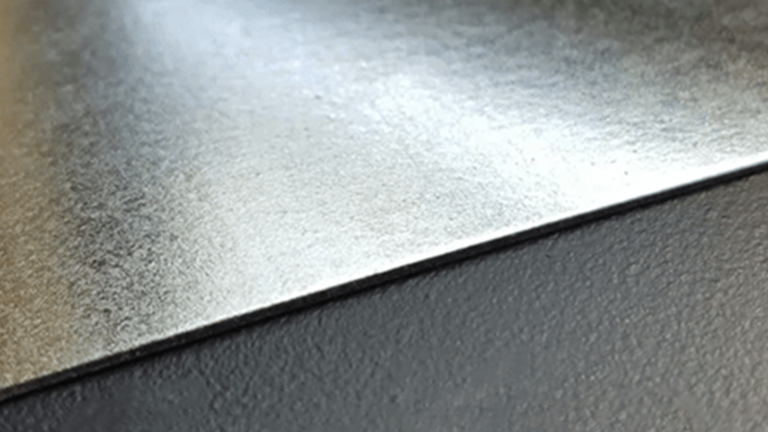

2.6 galvanized steel

Galvanized steel is a metal that has rust-resistant properties. These metals have a zinc coating that acts as an anti-rust agent and prevents further oxidation. This zinc coating prevents oxygen and water from entering the underlying steel.

Galvanized carbon steel offers excellent corrosion resistance, aesthetics and high recyclability. Manufacturers often use galvanized steel for automotive parts, construction components, and many other applications that require high corrosion resistance.

Methods to improve metal corrosion resistance

A metal is corrosion resistant if it can withstand the adverse effects of a particularly harsh environment. Manufacturers and product designers often use specific procedures to improve the corrosion resistance of metals because some metals are more resistant to corrosion than others. Here are some standard methods:

Anodizing: This electrochemistry method creates a controlled oxide film on the surface of metals such as titanium and aluminum. Aluminum oxide improves a metal’s corrosion resistance and other desirable properties, such as a stained or colored surface.

Surface Polishing: Polishing metal surfaces helps eliminate imperfections, create a smoother surface finish and reduce further corrosion. Therefore, surface polishing improves corrosion resistance and surface aesthetics.

Spray paint treatment: Spray paint forms a protective film on the metal surface. The coating acts as a barrier to prevent corrosive elements and moisture from entering the metal surface. However, you must carefully prepare the metal surface and choose the right paint or coating to get the best results.

Electroplating: Electroplating is an electrolytic process that improves the surface of a metal by depositing one metal onto another. Coatings or deposits form a protective barrier and increase the metal’s corrosion resistance. Nickel, chromium and zinc are typical metals used for electroplating.

Corrosion-resistant metals are processed materials with inherent properties that prevent degradation caused by exposure to corrosive elements or environments.