You can use different methods to create a protective coating on your knives. These methods include physical vapor deposition (PVD) and chemical vapor deposition (CVD). Among these methods, CVD is a popular and versatile technique that can deposit high-quality coatings.

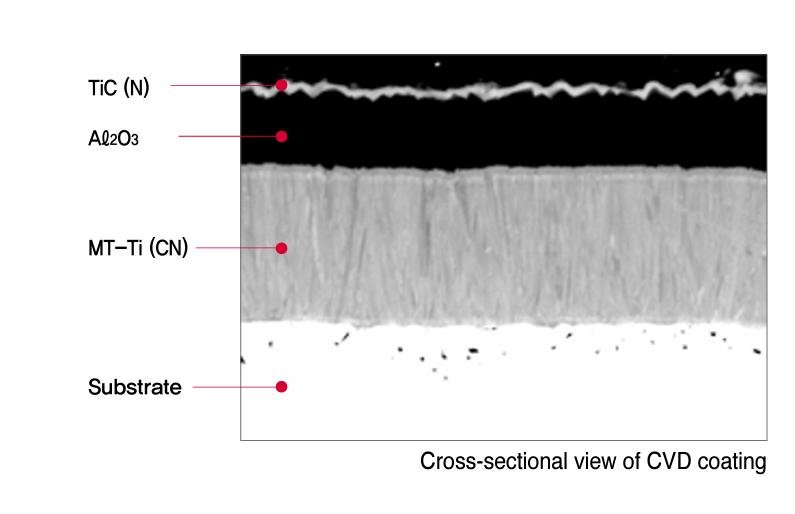

For example, aluminum powder suppliers can synthesize alumina (Al2 O3) from aluminum trichloride (AlCl3 ), oxygen (O2), and argon. But argon does not react with AlCl3 and O2 to form compounds. Instead, the CVD process uses this inert gas to dilute the oxygen and deliver it to the reactor.

There are many types of CVD processes, such as plasma-assisted CVD and atmospheric pressure CVD. Although the operating conditions of these processes vary, three main factors are generally required to successfully deposit bulk materials:

1.1 Volatile precursors

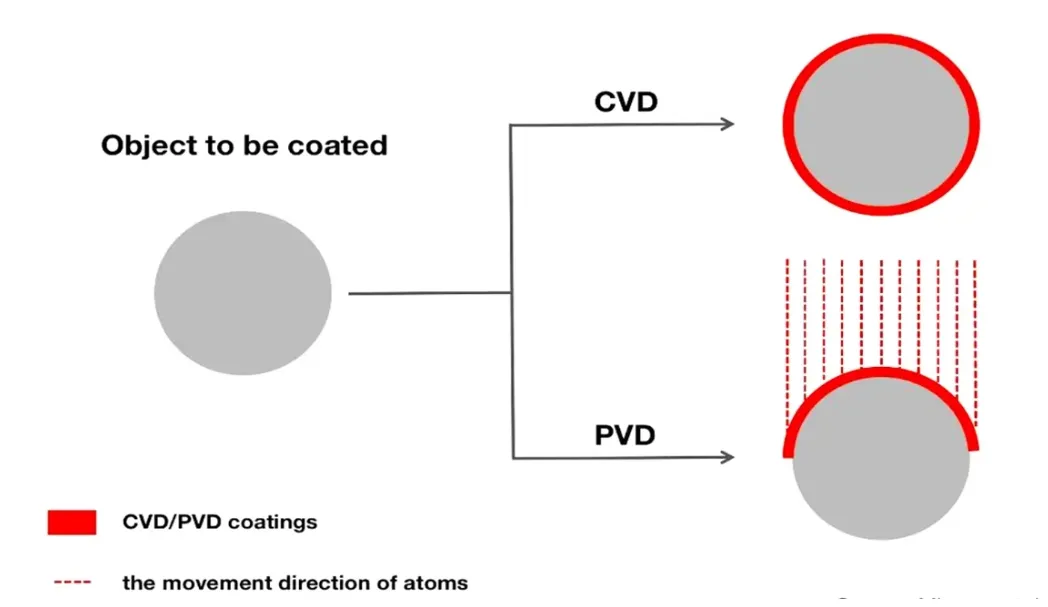

The precursors in the CVD process must be volatile. This is because CVD will use gas molecules to deposit a solid coating. This technology differs from physical vapor deposition (PVD), which bombards a solid source material into atoms and deposits these atoms on a substrate.

1.2 Vacuum chamber

The vacuum environment has a lower pressure, which can limit unnecessary reactions and make the thickness of the material deposited on the substrate more uniform.

1.3 High temperature

The CVD process requires high temperature because the precursor is deposited at extremely high temperatures, such as silane (SiH4) at 300-500°C or TEOS (Si(OC2H5)4) at 650-750°C. In addition, high temperatures can increase reaction rates. At high temperatures, gas molecules move faster and collide with each other more frequently. The reaction rate will increase accordingly.

How CVD works

The CVD coating process consists of the following basic steps:

The substrate to be coated is placed into the reaction chamber, and the producer adds a mixture of volatile precursors and inert gases into the chamber.

The substrate is then heated by resistive heating (e.g. tube furnace), microwave power, laser or plasma. At the same time, the pressure in the chamber will be reduced to activate the chemical reaction of the gas mixture.

The gas mixture then decomposes or reacts with the substrate material, depositing a thin film coating. Chemical reactions of mixed gases produce volatile by-products. For example, in the CVD process, when tungsten hexafluoride (WF6) and hydrogen (H2) deposit tungsten (W), hydrogen fluoride (HF) is produced as a gaseous by-product, as follows: WF6 + 3 H2 → W + 6 HF. The gaseous by-products are then removed from the vacuum chamber and properly disposed of to avoid contamination of the environment.

Advantages of chemical coatings

CVD allows suppliers to create coatings of uniform thickness and extremely complex shapes. With CVD, suppliers can apply thin-film coatings to the interior, bottom, high-aspect ratio holes and other complex features of materials.

This is something that PVD cannot do. This is because PVD is a line-of-sight coating process. This means that the particles used to form the coating move directionally from the solid source material to the substrate. The result is that PVD cannot create a uniform thickness on all surfaces of the substrate. In order for a substrate to be evenly coated with PVD, manufacturers must rotate the substrate to ensure that all molecules cover all surfaces. This ends up wasting time and money.

To better understand how molecules cover objects in CVD and PVD, take a look at the image below:

Another advantage of CVD is the very high purity of the CVD coating. This is because the CVD process involves applying distillation techniques to extract impurities from gaseous precursors.

CVD coatings are also high quality, waterproof and fine grained. Additionally, they are stronger than similar materials produced by traditional manufacturing processes. This is because the reaction of the volatile precursors with the substrate can form stronger bonds on the substrate surface.

Last, but not least, CVD has a higher deposition rate. However, the temperature and duration of CVD must be adjusted to control the coating thickness on the substrate.

Disadvantages of chemical coatings

CVD also has some disadvantages.

First, the precursor must be volatile in order to decompose or react with the substrate. But if these precursors are fully functional, they may be fed into a vacuum chamber before evaporating. This is why it is crucial to select and preserve precursors to limit their evaporation.

Secondly, some CVD precursors (such as Cu(acac)2, B2H6 or Ni(CO)4) are toxic, corrosive and explosive. If these gaseous precursors are not preserved and transported, they may have adverse effects on the environment and the health of those exposed to these gases.

Third, gaseous by-products such as HF, H2 or CO are highly toxic. Therefore, when these gases are released from the vacuum chamber, they must be handled appropriately.

Finally, the CVD process deposits thin film coatings at extremely high temperatures. However, some base materials have poor thermal stability. Therefore, choosing a substrate material that cannot withstand high temperatures may result in CVD process failure.

For example, at 150°C, aluminum alloys begin to weaken. At the same time, some precursors (such as silanes) are deposited in the temperature range of 300-500 °C. If a manufacturer chooses silane as the precursor gas to react with an aluminum substrate, the chemical reaction can corrode the substrate. Therefore, manufacturers must consider the substrate material and its thermal stability when selecting volatile precursors.

Summarize

Chemical vapor deposition is one of the most effective methods for protective coatings of electronic components and semiconductor components.

CVD is simple. But for this coating process to be successful, strict guidelines regarding temperature, precursor volume, substrate material, chamber material, pressure, and duration must be adhered to. CVD offers several advantages and is often able to create a uniform thickness on the substrate. But its disadvantage is that some gaseous precursors and by-products in CVD are toxic. Therefore, those engaged in CVD processes must adhere to standard operating procedures (SOPs) to ensure their health and environmental safety.