▼ Technical knowledge of coating

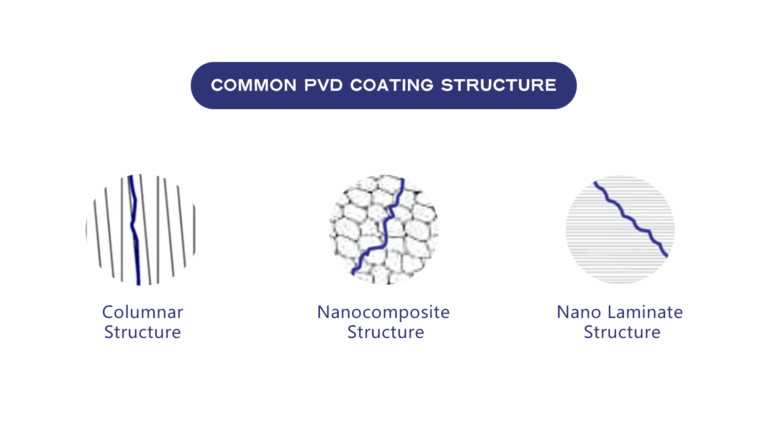

The coating is a very thin (micron thick) compound coating that adheres firmly to the surface of the tool. Coatings have the following advantages for precision tools:

- Increased service life/wear resistance

- Friction and wear occur on the surface between two moving parts, such as a workpiece and a drill bit. This friction puts stress on the drill bit, and the coating can reduce this stress. This extends the life of the tool.

- Increase feed

- Cutting speed can be increased due to the protection of the coating.

- Anti-corrosion

- The coating protects the tool from negative environmental effects such as rust.

- Good visual effect

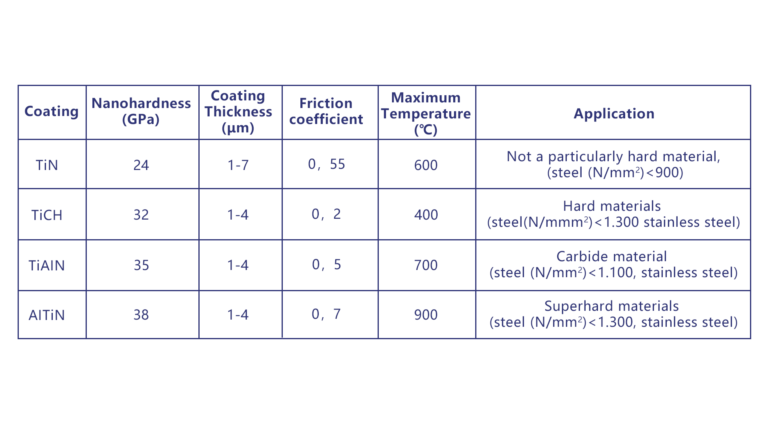

Coating thickness is measured in micrometers (μm) and should not exceed 0.7 μm, as thicker layers are prone to cracking. Depending on the material to be machined and the precision tool selected, the need for tool coating must be considered. Two factors play an important role here:

1.Application, that is, the workpiece material to be processed

Is it mild steel, stainless steel or aluminum? The harder the material, the higher the

2.Cutting type (such as drill, milling cutter, thread)

For example, threading requires a slower turning angle than twist drill drilling, so the maximum temperature it can withstand is different.

▼ Improving tool life

The definition of tool service life: that is, the maximum time for the tool to reach allowable wear. In other words: service life is the limit of time before you are no longer satisfied with the drilling results or the tool performance is affected.

In addition to the coating, tool service life also depends on:

- Cutting speed

- Materials

- Tool steel

- Chip cross section (cutting size)

- Cool down

- Machine tool category and operation (guided, manual)

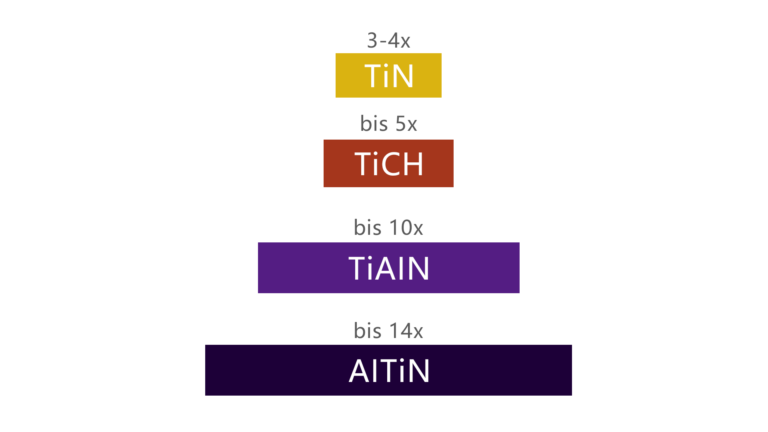

A major benefit of coatings is extended service life of precision tools. Even TiN, the most commonly used standard coating, can increase tool life by three to four times. Therefore, if you are making bulk parts and do not want to buy a new drill bit every week, you should choose a coated drill bit. You can also extend the service life by cooling it.

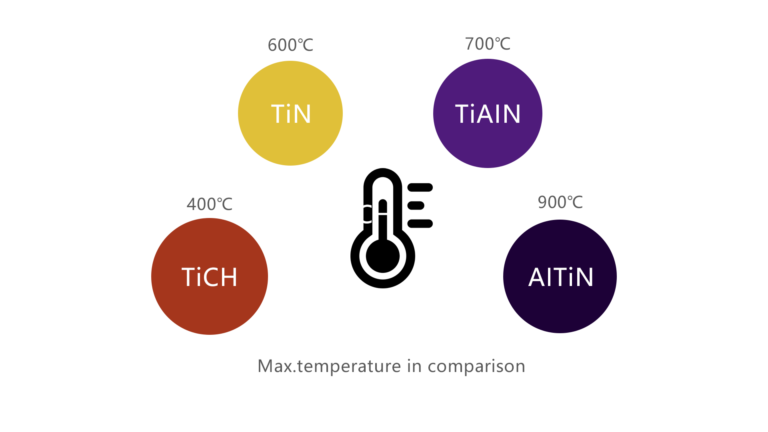

▼ Maximum cutting speed and maximum application temperature

Cutting speed is expressed in meters per minute (m/min). During the cutting process, the cutting edge of the tool wears due to friction, cracking and diffusion at high temperatures. This changes the geometry of the cutting edge, reducing tool quality and machining accuracy. By setting precise cutting speeds, you can achieve optimal machining results and minimize tool wear. As mentioned above, the cutting speed required for threading is lower than that required for drilling. The maximum application temperature depends on the cutting speed. The higher the cutting speed, the higher the maximum application temperature required for coating maturation.

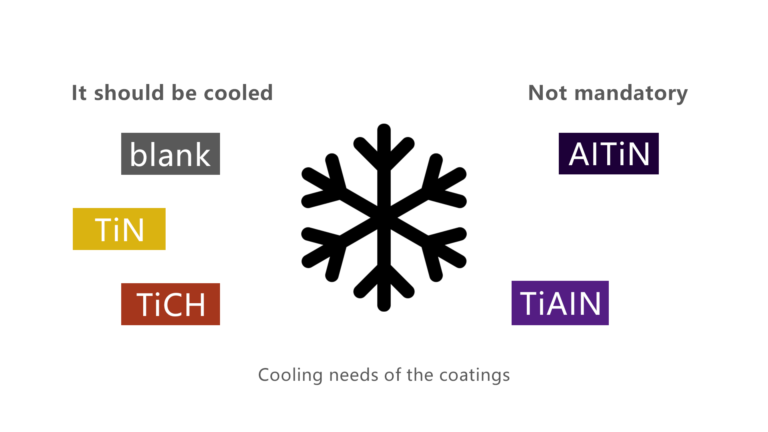

▼ Cooling

Regardless of coating, cooling has a positive effect on the tool. Therefore, we always recommend cooling during processing, even if it is not absolutely necessary.

- Coolant ensures

- Reduce friction

- Take away chips

- Take away heat

- Increase tool life

- Improve workpiece surface quality

- Clean the workpiece

- Avoid corrosion

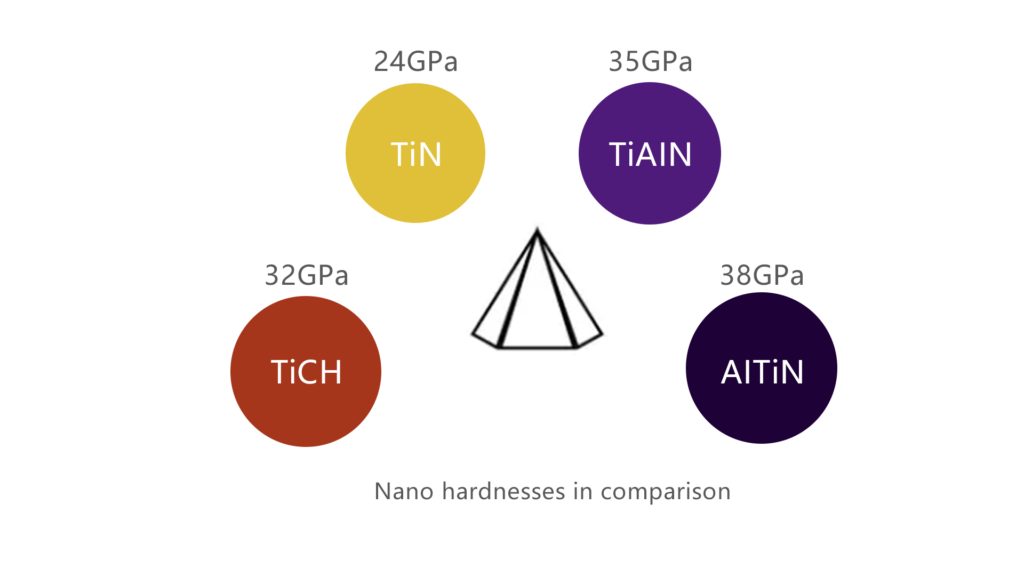

▼ Nanoscale hardness

Nano-hardness is expressed in gigapascals (GPa), which represents the pressure exerted by one Newton of force over an area of one square meter (The formula is: 1 kg·m−1·s−2 = 1n·m−2).

Tools with nano-hardness can cut harder materials and achieve higher cutting speeds. This has a positive impact on the required processing time.

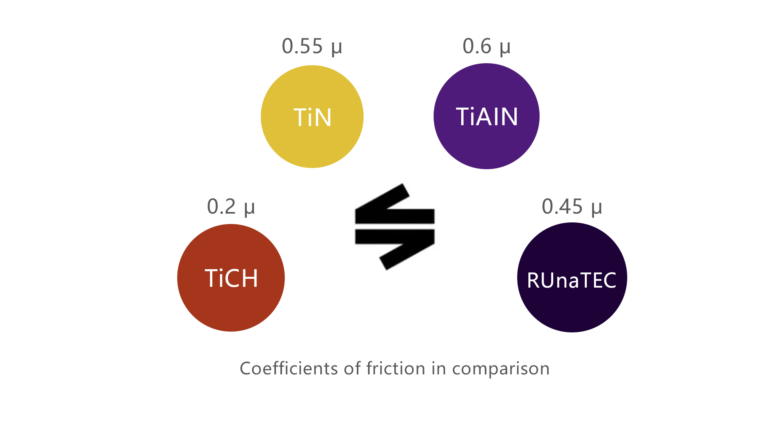

▼ Friction coefficient

During the hole machining process, the moving tool comes into contact with the static material. This creates friction and corresponding heat. The purpose is to transmit force with low friction.

The coefficient of friction is expressed in μ. For example, the friction coefficient between steel and steel can be reduced from 0.2 to 0.07 μ through cooling.

▼ Summary

Coatings always have a positive effect on knives. Depending on the area of application, it is advantageous to use different coatings. The table below shows you a comparison of the different technical parameters and application areas of the four coatings.