What is coating?

Tool coatings consist of organic and inorganic compounds that are applied using physical vapor deposition (PVD) or chemical vapor deposition (CVD) and adhere to the substrate. The compound is deposited layer by layer on the tool until the desired thickness is reached.

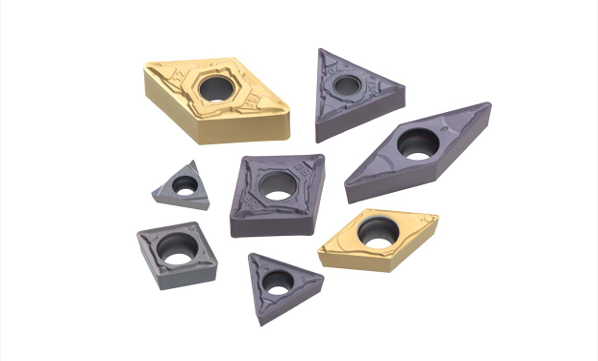

Coated cutting tools have three main functions:

1. Provide a thermal barrier between tool and workpiece

2. Improve tool lubricity

3. Improve tool wear resistance

By properly leveraging these three properties, cutting tools can achieve greater thrust, faster cycle times, and longer service life.

1. Overview of PVD coating

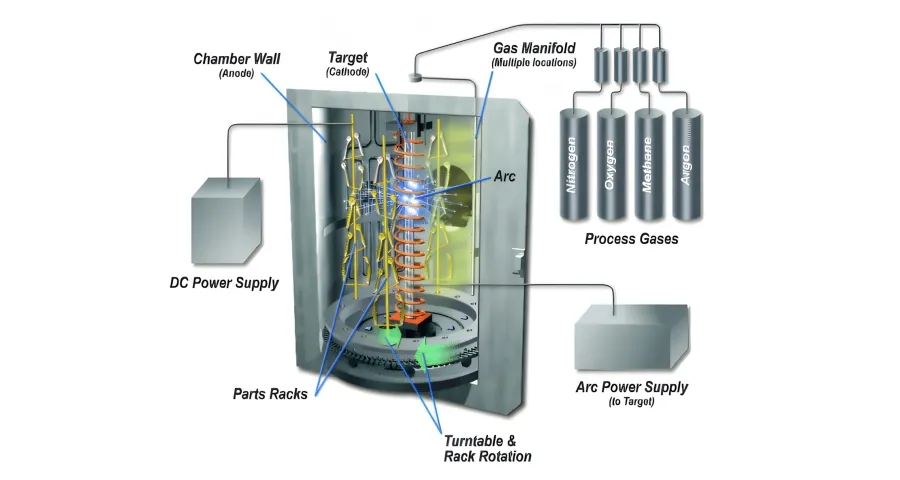

The physical vapor deposition (PVD) process deposits coatings by bombarding the material with a hot plasma discharge. The magnet then directs the plasma discharge to the target area and sputters the material to deposit the PVD coating. The history of PVD is closely tied to the discovery of electricity, magnetism, and the understanding of gaseous chemical reactions. Otto van Guericke invented the first piston vacuum pump in 1640. The process was so effective that it was soon being used to mine water and create a new type of water.

PVD coating uses a high-tech vacuum process to evaporate special materials. The evaporated material is deposited in a thin layer on the selected object. When a reactive gas (such as nitrogen, oxygen, or hydrocarbon gas) is introduced into a metal vapor, the metal vapor stream chemically reacts with the gas to produce a nitride, oxide, or carbide coating. PVD coating must be performed in a specialized reaction chamber so that the evaporated material does not react with any contaminants originally present in the room.

During the PVD coating process, process parameters are closely monitored and controlled so that reproducible film hardness, adhesion, chemical resistance, film structure and other properties are achieved every run. Various PVD coatings are available to increase wear resistance, reduce friction, improve appearance and achieve other performance

2. What is PVD coating treatment

PVD coating is an advanced surface treatment technology that can change the properties of metals at the molecular level. The process takes place in a high-tech vacuum chamber and uses precious metals or a combination of precious metals and charged gases to form thin layers of the desired material. This coating is highly resistant to corrosion and oxidation.

Unlike other coating processes, PVD requires a vacuum chamber and special equipment to apply the surface treatment. The result is a very thin coating, typically between 0.5 microns and 5 microns thick. PVD coatings are used in many different applications, but are most commonly used on stainless steel. The result is a variety of interesting looks and textures. Due to its extremely thin nature, PVD coatings are difficult to remove.

3. PVD coating working process

Physical Vapor Deposition (PVD) is one of the common methods for preparing films and coatings. Its basic principle is the transformation process of materials from solid to gaseous state. This process typically involves sputtering, evaporation, and heat treatment in an inert atmosphere. Physical evaporation deposition is performed in a vacuum chamber at temperatures typically between 50 and 600 degrees Celsius. The process utilizes a “straight-line view” method, in which atoms of solid materials pass through a vacuum chamber and embed themselves into objects in their path. During the deposition process, the object must be properly positioned in the vacuum chamber to achieve an even coating.

4. What is the thickness range of PVD coating

The thickness range of PVD coatings depends on the type of application. For example, a coating used to decorate stainless steel panels may be only 0.30 microns thick. For functional applications, thicknesses may range from two to five microns. The hardness of the coating will depend on several factors, including lubricity, surface finish and type of motion. Published coefficient of friction values can vary significantly, so it is important to understand the actual range.

Ion bombardment of the PVD coating increases its density, reduces porosity, and increases the hardness of the membrane. This hardness will help improve the corrosion resistance of the film. PVD coatings are typically produced by two common PVD technologies, arc vaporization and sputtering. The latter process uses an intense electron beam to deposit the coating onto the substrate, resulting in a higher degree of ionization. The average ionization level is about 2.

5. What is the hardness of PVD coating?

Studies have found that there is no direct relationship between hardness and wear resistance. Metal coatings have optimal hardness values and increasing them increases the integrity of the coating. Hardness values exceeding this threshold indicate decarburization, i.e. the formation of additional hard phases. PVD coatings have optimal hardness levels, with higher values indicating more damage than lower values.

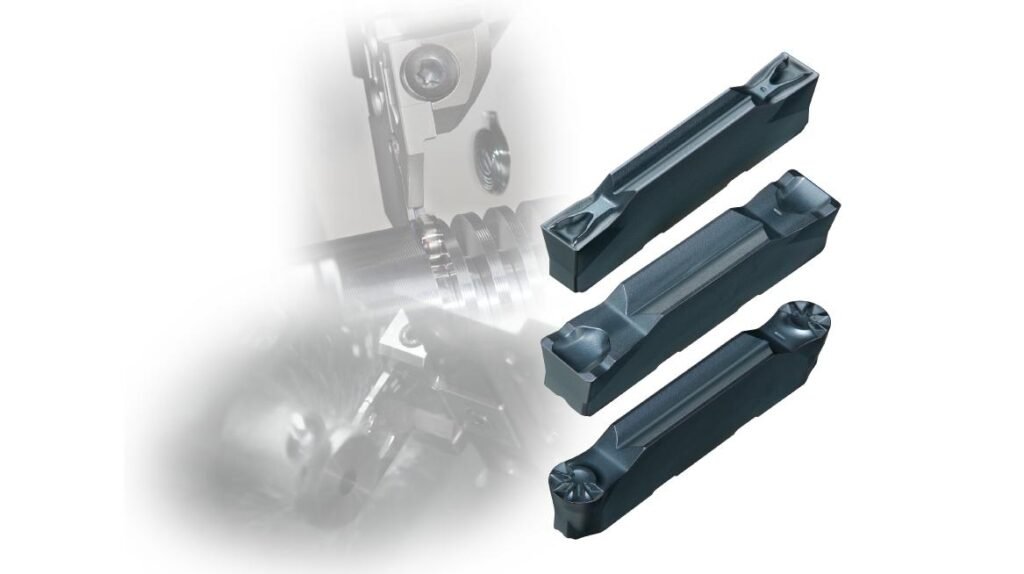

The benefits of PVD coating are many. They improve the performance of cutting tools. For example, cathodic arc PVD coating services can extend tool life up to 10 times. They also provide a harder, more lubricating and more wear-resistant surface.

6. What is the hardness of PVD coating?

The process of physical vapor deposition (PVD) involves evaporating materials onto a substrate. The material being evaporated can be inorganic or organic. They are suitable for applications requiring a harder, more resistant microscopic loss of wear. The process is very environmentally friendly and the materials are very clean and pure. This makes them ideal coatings for surgical implants.

This process is easy to perform and produces no contaminants. By using thin layers of material, it creates a material with the desired properties. This enables users to design and build various types of materials. Some common applications of PVD include optical film deposition, semiconductor devices, aluminized PET films, coated cutting tools and other types of coatings. In addition to coatings, PVD can also produce highly reflective films.

7. Benefits of PVD coating surface treatment

The basic principles of PVD coating involve the control of gas and time. Inert gases, such as argon, are used to create a chemically inactive environment. The end result is a very thin protective coating that maintains the aesthetics and sound quality of the previous stage. This is a very popular strategy.

- The properties of PVD coatings depend on the base material. For example, when TiN coating is applied to Ti-6Al-4V alloy, it can increase the fatigue limit by 22% and the durability by 7%. These properties help determine the durability of PVD coatings. The hardness of a coating is an important factor in determining its durability.

PVD coating is also available in color options. Many buildings already use PVD colored stainless steel panels. PVD coatings are extremely hard and resistant to discoloration and pitting, as well as being extremely resistant to sandblasting and bleaching. Additionally, a colorful PVD coating can help make your beachfront property stand out, keeping it looking vibrant for years to come.

The PVD process is more environmentally friendly than electroplating. No harmful gases are released or water waste is produced. In addition, PVD coatings are recyclable, protecting the value of stainless steel-based materials. It is widely used in multiple industries such as telecommunications and automobiles. The process has few environmental by-products. In addition, PVD coating is also the first choice of many people.

PVD is a superior coating for most steel products. It is four times harder than chrome and therefore more resistant to scratches and corrosion. PVD coatings also last longer, making them ideal for projects exposed to harsh environments, close to shore or with frequent contact.

The PVD process will form a coating several microns thick on the base material, which is very tightly bonded to the base material. This means it won’t flake or flake because it interpenetrates with the substrate. It is worth mentioning that PVD is very different from anodizing, painting and powder coating. PVD is made from a material called diamond-like carbon that is sprayed onto a metal surface and cooled quickly.

PVD process is widely used in many fields such as aerospace and automotive original parts. This ultra-thin coating is extremely durable and available in a variety of metallic color options. Not only do these coatings look great, they reduce friction and damage. Additionally, the process can be used to coat plastics and harden metal parts. In addition to its advantages in the engineering field, PVD coatings also offer high corrosion and scratch resistance.

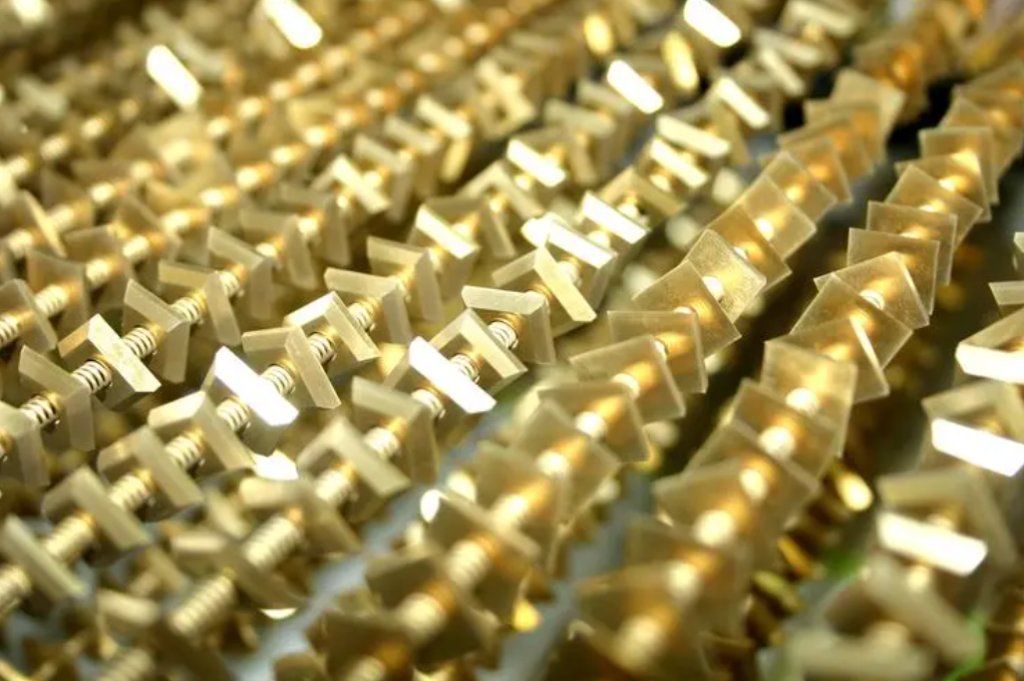

PVD coated gold electroplated metal is highly resistant to corrosion and scratches. Although gold plating is a cheaper alternative to metallic gold plating, it is not as durable and corrosion resistant as PVD coating. Gold plated metal may expose the base material when scratched. It is best to choose PVD coated metal.